Phse PhotoeClelectorcricsor Fenteror Labarai na ɗan gajeren nesa, mai girman-daidaitaccen cikakken bayani game da tsayin PCB. Sensor mai saurin shiga Laser yayi daidai gwargwado na abubuwan da aka haɗa PCB, wanda ya dace sosai kayan aikin tsayi da yawa.

Shin ka taɓa yin mamakin yadda allon PCB, zukatan na'urorin lantarki da muke amfani da su yau da wayo, kwamfutoci, da allunan, ana kera su? A cikin wannan madaidaici da tsarin samar da kayan aiki, biyu daga cikin "idanu masu wayo" aiki shiru, walan na'urori masu son su.

Gano layin samar da sauri inda aka sanya kayan haɗin lantarki da yawa inda ake bukatar a sanya su daidai a allon PCB. Kowane kuskure na minti zai iya haifar da gazawar samfurin. Photelectory na'urori masu son su, suna aiki kamar "ido ido" da kuma "dukkan-ji kunnuwa ga kayan aikin samarwa da inganci na samar da masana'antu.

Photexcity na'urori masu son kai da Photeeelectrics: idanun samar da PCB

Tattorancin firikwensin kamar yadda "mai ganowa ne" wanda zai iya jin nisa tsakanin abu da firikwensin. Lokacin da abu ya kusa, firikwensin ya fitar da sigina, in gaya wa na'urar, "Na samu kashi a nan!"

Photeelectrics ya fi kama da "fitilar haske," yana iya gano bayanai kamar ƙarfin haske da launi. Misali, ana iya amfani dashi don bincika ko kayan haɗin gwiwar soja akan PCB suna amintacce ne ko kuma idan launi na kayan haɗin daidai ne.

Matsakaici a layin samar da PCB ya fi kawai "gani" da "sauraro"; Suna kuma gudanar da ayyuka masu mahimmanci da yawa.

Aikace-aikacen TOREXIMITI DA PHINELEELOCRACH SARKI A PCB

Hukumar sarrafawa

- Abubuwan da aka gano da aka gano:

Abubuwan da ke wakilta na fice na iya gano su daidai ko an sanya kayan haɗin da kyau, tabbatar da amincin hukumar PCB. - Gano tsayin hangen nesa:

Ta wajen gano tsayin daka, ingancin soji za a iya ƙaddara shi, tabbatar da cewa abubuwan da aka gyara ba su da ƙarfi sosai kuma ba su da ƙarfi sosai.

Binciken PCB din

-

- Ma'aunin ma'auni:

Photoeelectriccs na iya auna daidai da girman allon PCB, tabbatar sun gama bukatun zane. - Gano launi:

Ta hanyar gano alamun launi akan hukumar PCB, ana iya ƙaddara ko an sanya kayan daidai. - Gano ganowa:

Photoeelectriccys na iya gano lahani akan allon PCB kamar sucratches, bata bashin jan karfe, da sauran ajizai.

- Ma'aunin ma'auni:

Tsarin sarrafawa

- Kayan aiki:

Hanyoyi masu mahimmanci na iya ganowa daidai inda allon PCB don aiki mai zuwa. - Kayan aiki:

Photoeelectrics na'urori masu son su na iya ƙidaya allon PCB yayin da suke wucewa, tabbatar da cikakken adadin samarwa.

Gwaji da daidaitawa

-

- Gwajin Tallafi:

Masu aikin kwalliya na kusanci da na iya gano ko shinge a kan kwamitin PCB sun gajarta ko buɗe. - Gwajin gwaji:

Photoeelectriccys na iya aiki tare da wasu kayan aiki don gwada ayyukan kwamitin PCB.

- Gwajin Tallafi:

Kayan da aka ba da shawarar da suka shafi lanbao

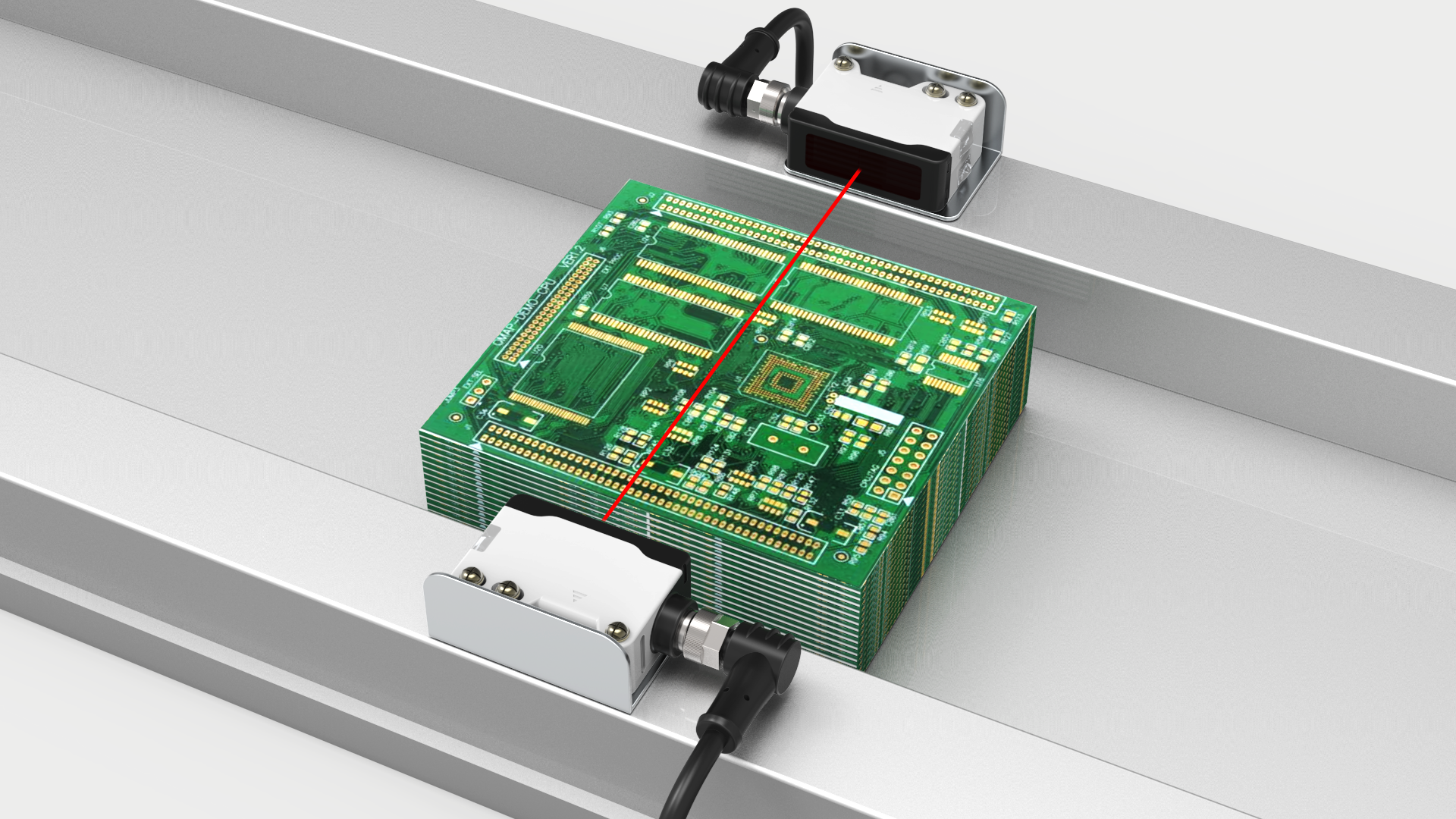

PCB Sako Stick Gano Matsayi

-

- Pse - Bated-Bature Photeelectrics:

- Distance Distance: 5m, 10m, 20m, 30m

- Gano tushen hasken: Red Lightared, Red Laser

- Matsayi girman: 36m @ 30m

- Fitar da wutar lantarki: 10-30v DC DC NPN PNP kullum bude da kuma kullun rufe

- Pse - Bated-Bature Photeelectrics:

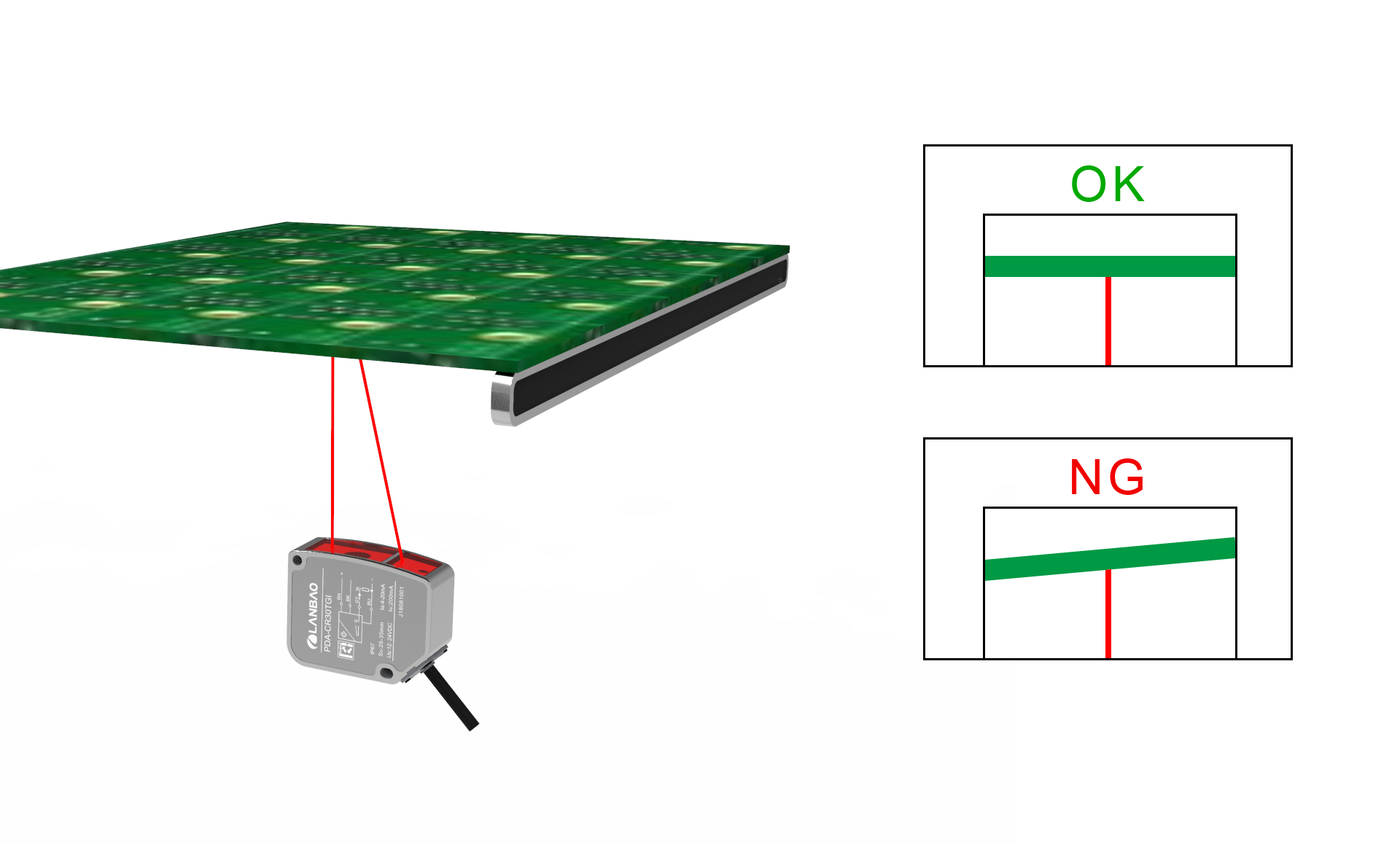

Substrate Warfan Warpage

Ta amfani da samfurin PDA-CR don auna tsayi da yawa na wurare da yawa na PCB na Substrate, warpage za a iya tantancewa ta tantance ko ƙimar high.

-

- PDA - Laserididdigar Laser

- Aluminum na aluminum, sturdy da m

- Matsakaicin daidaito har zuwa 0.6% FS

- Babban ma'aunin ma'auni, har zuwa mita 1

- Daidaito na hijira har zuwa 0.1%, tare da ƙaramin sigogi

- PDA - Laserididdigar Laser

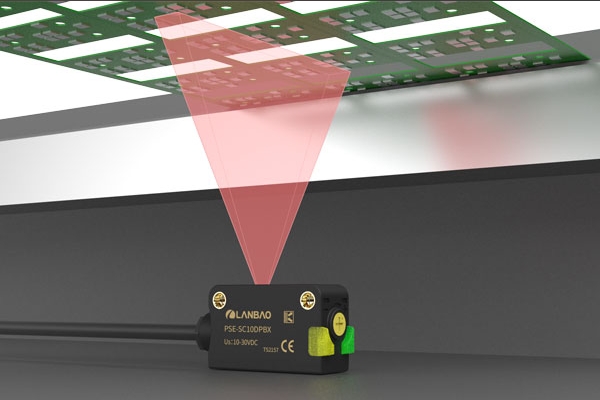

Gano PCB

Daidai ya jawo da kuma amincewa da PCBS ta amfani da PSE - Limit Lissafi jerin.

Me yasa ake buƙata?

- Inganta Ingancin samarwa: Autuwa a ganowa da sarrafawa suna rage madaidaicin aikin hannu da haɓaka haɓaka samarwa.

- Tabbatar da ingancin samfurin: Tabbatar da cewa samfuran suna haɗuwa da buƙatun tsara zane da kuma rage ƙarancin lahani.

- Haɓaka sassauci: Daidaita ga nau'ikan samar da PCB yana ƙara sassaucin layin samarwa.

Ci gaban gaba

Tare da ci gaba na ci gaba na fasaha, aikace-aikacen na'urori masu auna na'urori da Photeelectrics a masana'antar PCB za su zama da zurfi da zurfin ciki. A nan gaba, zamu iya tsammanin gani:

- Smallerari mai girma: Sensors zai ƙara miniamarazed kuma har ma a haɗe shi cikin ƙananan abubuwan lantarki.

- Ingantarwa Ayyuka: Sensors zai iya gano kewayon yawan adadin mai yawan gaske, irin su zafi, da matsin iska.

- Lowerarancin farashi: Rage a farashin firikwensin zai fitar da aikace-aikacen su a cikin ƙarin filayen.

Photelectory na'urori masu sonta hoto, ko da yake kanana, suna taka muhimmiyar rawa a rayuwarmu. Suna yin samfuran lantarki mai wayo da kawo ƙarin dacewa a rayuwarmu ta yau da kullun. Wannan fassarar tana kula da ma'anar ainihin kuma mahallin tabbatar da haske da haɗuwa a Turanci.

Lokaci: Jul-23-2024