I-PSE nge-beam photoelectric sensor yenza ukuba umgama omfutshane, ukubeka iliso oluchanekileyo lobude be-PCB. I-laser displacement sensor ilinganisa ngokuchanekileyo umphakamo wamacandelo e-PCB, ngokufanelekileyo ukuchonga amacandelo amade kakhulu.

Ngaba ukhe wazibuza ukuba zenziwa njani iibhodi zePCB, iintliziyo zezixhobo zombane esizisebenzisa mihla le njengee-smartphones, iikhompyutha kunye neetafile? Kule nkqubo yemveliso echanekileyo nentsonkothileyo, iperi "amehlo ahlakaniphileyo" asebenza ngokuzolileyo, oko kukuthi, i-proximity sensors kunye ne-photoelectric sensors.

Yiba nomfanekiso-ngqondweni wemveliso enesantya esiphezulu apho izinto ezincinci ze-elektroniki kufuneka zibekwe ngokuchanekileyo kwiibhodi zePCB. Nayiphi na impazamo yomzuzu ingakhokelela ekungaphumeleli kwemveliso. Izinzwa ezikufutshane kunye ne-photoelectric sensors, ezisebenza njenge "Iliso Lokubona Konke" kunye ne "All-Hearing Ear" yomgca wokuvelisa we-PCB, inokubona ngokuchanekileyo indawo, ubuninzi, kunye nobukhulu bamacandelo, ukubonelela ngengxelo yexesha langempela kwisixhobo sokuvelisa, ukuqinisekisa ukuchaneka kunye nokusebenza kakuhle kwayo yonke inkqubo yokuvelisa.

IiSensors ezikufutshane kunye ne-Photoelectric Sensors: I-Eyes of PCB Production

Isivamvo sokusondele sifana "nesixhobo sokubona umgama" esikwaziyo ukubona umgama phakathi kwento kunye nesixhobo soluvo. Xa into isondela, inzwa ikhupha umqondiso, ixelela isixhobo, "Ndinento apha!"

I-sensor ye-photoelectric ifana "nomcuphi okhanyayo," okwazi ukufumanisa ulwazi olufana nokukhanya kunye nombala. Umzekelo, ingasetyenziselwa ukujonga ukuba ngaba amalungu e-solder kwi-PCB akhuselekile okanye ukuba umbala wezinto ulungile.

Indima yabo kumgca wemveliso we-PCB ingaphezulu kakhulu "kokubona" kunye "nokuphulaphula"; kananjalo benza imisebenzi emininzi ebalulekileyo.

Usetyenziso lwe-Proximity kunye ne-Photoelectric Sensors kwi-PCB Production

Ukuhlolwa kwecandelo

- Ilungu Elilahlekileyo:

Abenzi boluvo abasondele banokubona ngokuchanekileyo ukuba amacandelo afakwe ngokufanelekileyo, ukuqinisekisa ukuthembeka kwebhodi yePCB. - Ukubonwa koBude becandelo:

Ngokufumanisa ukuphakama kwamacandelo, umgangatho we-soldering unokumiselwa, ukuqinisekisa ukuba amacandelo awaphezulu kakhulu okanye aphantsi kakhulu.

Ukuhlolwa kwebhodi yePCB

-

- Umlinganiselo woMda:

Abenzi boluvo be-Photoelectric banokulinganisa ngokuchanekileyo imilinganiselo yeebhodi zePCB, ziqinisekisa ukuba ziyahlangabezana neemfuno zoyilo. - Ukufunyanwa kombala:

Ngokubona iimpawu zombala kwibhodi yePCB, kunokuqinisekiswa ukuba amacandelo afakwe ngokuchanekileyo na. - Ukufunyanwa Kwesiphene:

Abenzi boluvo befoto bombane bayakwazi ukubona iziphene kwiibhodi zePCB ezinje ngemikrwelo, ifoyile yobhedu engekhoyo, kunye nezinye iziphene.

- Umlinganiselo woMda:

Ulawulo lweNkqubo yeMveliso

- Ukuma kweMathiriyeli:

Abenzi boluvo abasondele bangafumana ngokuchanekileyo indawo yeebhodi zePCB ukulungiselela ukusetyenzwa okulandelayo. - Ukubalwa kwezinto:

Iinzwa zefoto zombane zingabala iibhodi zePCB njengoko zidlula, ziqinisekisa ubungakanani obuchanekileyo bemveliso.

Uvavanyo kunye nokuCalibration

-

- Uvavanyo loQhagamshelwano:

Abenzi boluvo abasondele banokubona ukuba iipads kwibhodi yePCB zifutshane okanye zivuliwe. - Uvavanyo olusebenzayo:

Iinzwa zefoto zombane zinokusebenza ngokubambisana nezinye izixhobo zokuvavanya ukusebenza kwebhodi yePCB.

- Uvavanyo loQhagamshelwano:

Iimveliso ezicetyiswayo ezinxulumene ne-LANBAO

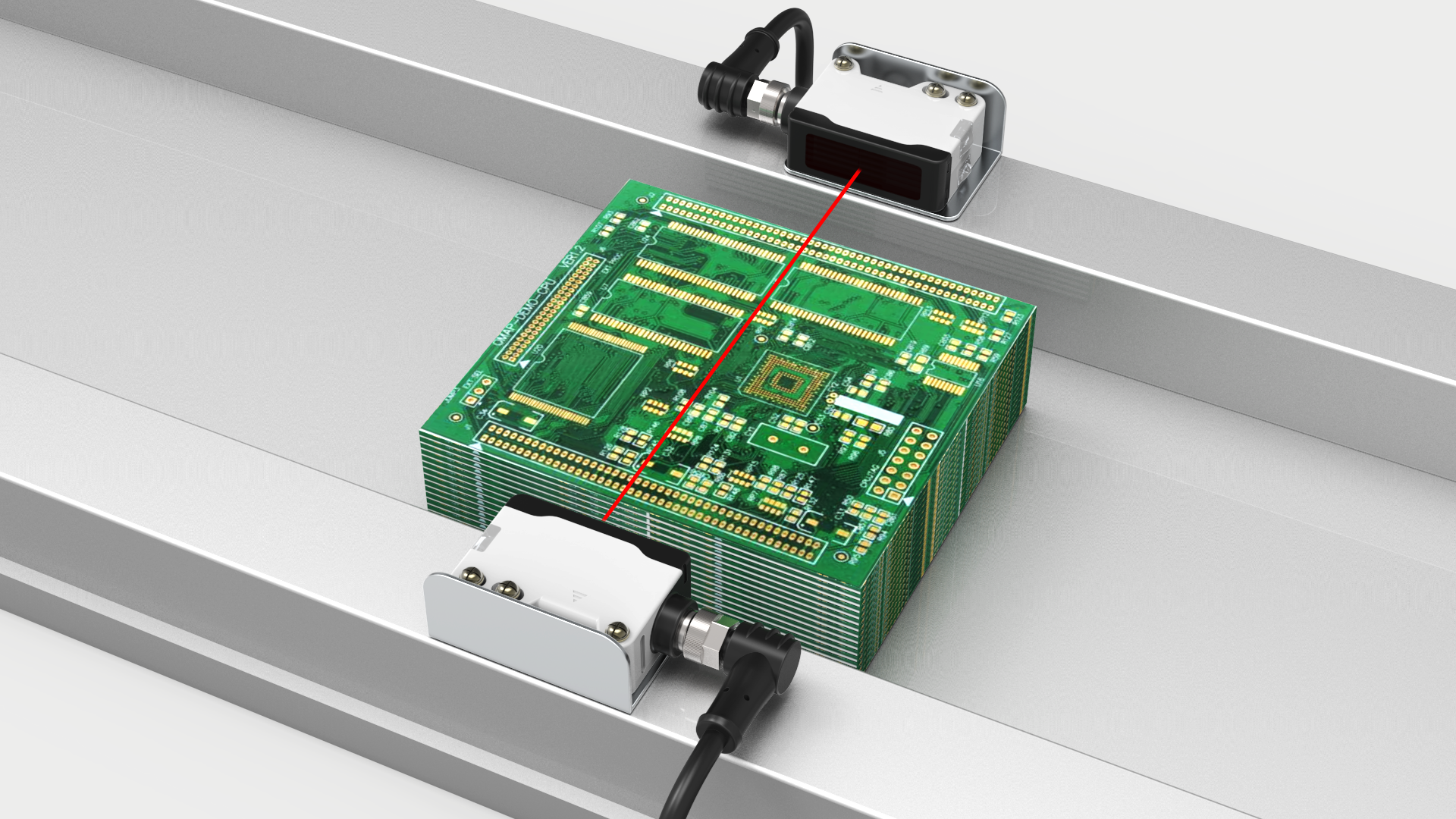

PCB Stack Height Position ukufunyanwa

-

- PSE-Nge-Beam Photoelectric SeriesFeatures:

- Umgama wokubona: 5m, 10m, 20m, 30m

- Umthombo wokukhanya wokubona: Isibane esibomvu, isibane se-infrared, i-laser ebomvu

- Ubungakanani bendawo: 36mm @ 30m

- I-Power Output: 10-30V DC NPN PNP idla ngokuvula kwaye ivalwe ngokuqhelekileyo

- PSE-Nge-Beam Photoelectric SeriesFeatures:

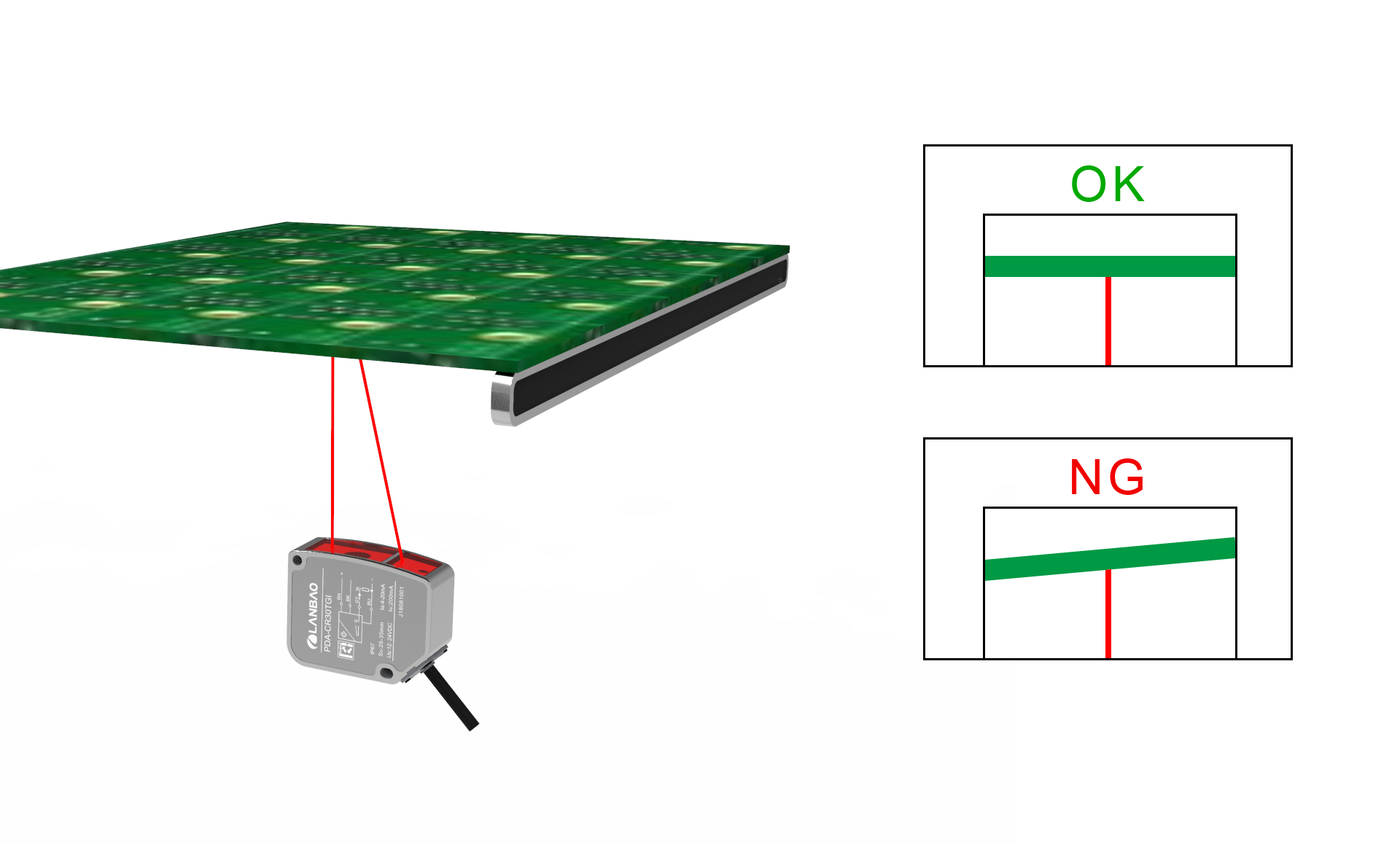

Ukufunyanwa kwephepha leWarpage engaphantsi

Ngokusebenzisa imveliso ye-PDA-CR ukulinganisa ubude beendawo ezininzi ze-PCB substrate, i-warpage inokumiselwa ngokuvavanya ukuba amaxabiso obude ayafana.

-

- PDA - Laser Distance Displacement Series

- Indlu yeAluminiyam, yomelele kwaye yomelele

- Ubuninzi bokuchaneka komgama ukuya kuthi ga kwi-0.6% FS

- Uluhlu lomlinganiselo omkhulu, ukuya kuthi ga kwimitha eyi-1

- Ukuchaneka kokufuduswa ukuya kuthi ga kwi-0.1%, kunye nobungakanani bendawo encinci kakhulu

- PDA - Laser Distance Displacement Series

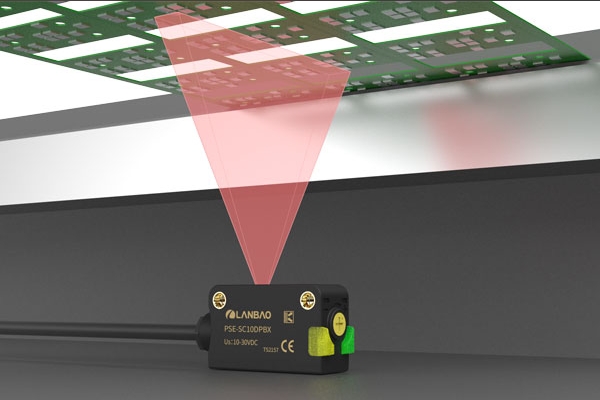

PCB Uqwalaselo

Ukuqonda okuchanekileyo kunye nokuqondwa kwee-PCBs usebenzisa i-PSE - i-Limited Reflection Series.

Kutheni Zifuneka?

- Ukuphucula ukusebenza kakuhle kweMveliso: Ukuzenzekela ekubhaqweni nasekulawuleni kunciphisa ungenelelo lwezandla kunye nokwandisa ukusebenza kakuhle kwemveliso.

- Ukuqinisekisa uMgangatho weMveliso: Ukufunyanwa ngokuchanekileyo kuqinisekisa ukuba iimveliso zihlangabezana neemfuno zoyilo kwaye zinciphisa izinga lesiphako.

- Ukuphucula ukuguquguquka kweMveliso: Ukuguquguquka kwiintlobo ezahlukeneyo zemveliso ye-PCB kwandisa ukuguquguquka komgca wemveliso.

Uphuhliso lwexesha elizayo

Ngenkqubela phambili yetekhnoloji eqhubekayo, ukusetyenziswa kwezinzwa ezikufutshane kunye ne-photoelectric sensors kwi-PCB yokuvelisa kuya kusasazeka ngakumbi kwaye kunzulu. Kwixesha elizayo, sinokulindela ukubona:

- Ubukhulu obuNcinci: I-Sensors iya kunyuka i-miniaturized kwaye inokudityaniswa nezinto ezincinci ze-elektroniki.

- Imisebenzi eyandisiweyo: Iinzwa ziya kukwazi ukubona uluhlu olubanzi lobungakanani bomzimba, obufana nobushushu, ukufuma, kunye noxinzelelo lomoya.

- Iindleko eziphantsi: Ukunciphisa iindleko zenzwa kuya kuqhuba isicelo sabo kwiinkalo ezininzi.

Izinzwa ezisondele kunye ne-photoelectric sensors, nangona zincinci, zidlala indima ebalulekileyo ebomini bethu. Benza iimveliso zethu ze-elektroniki zikrelekrele kwaye bazise lula ngakumbi kubomi bethu bemihla ngemihla. Olu guqulelo lugcina intsingiselo yoqobo kunye nomxholo ngelixa iqinisekisa ukucaca kunye nokuthungelana kwesiNgesi.

Ixesha lokuposa: Jul-23-2024