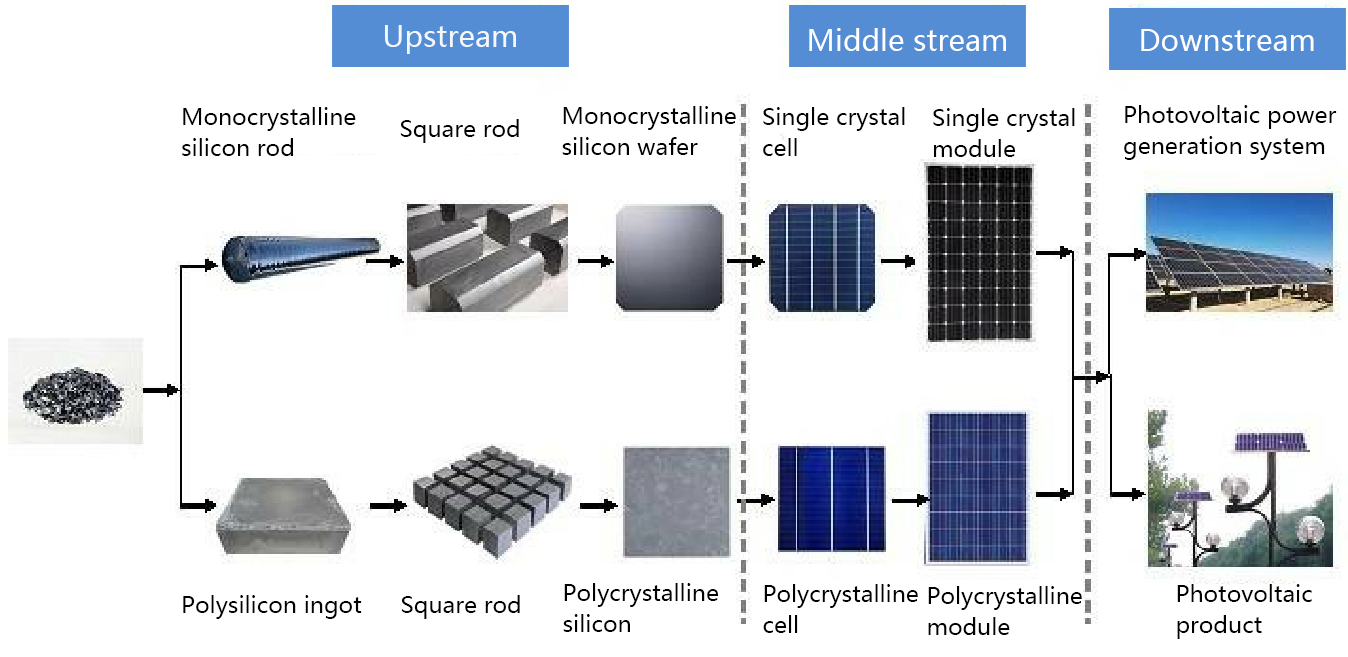

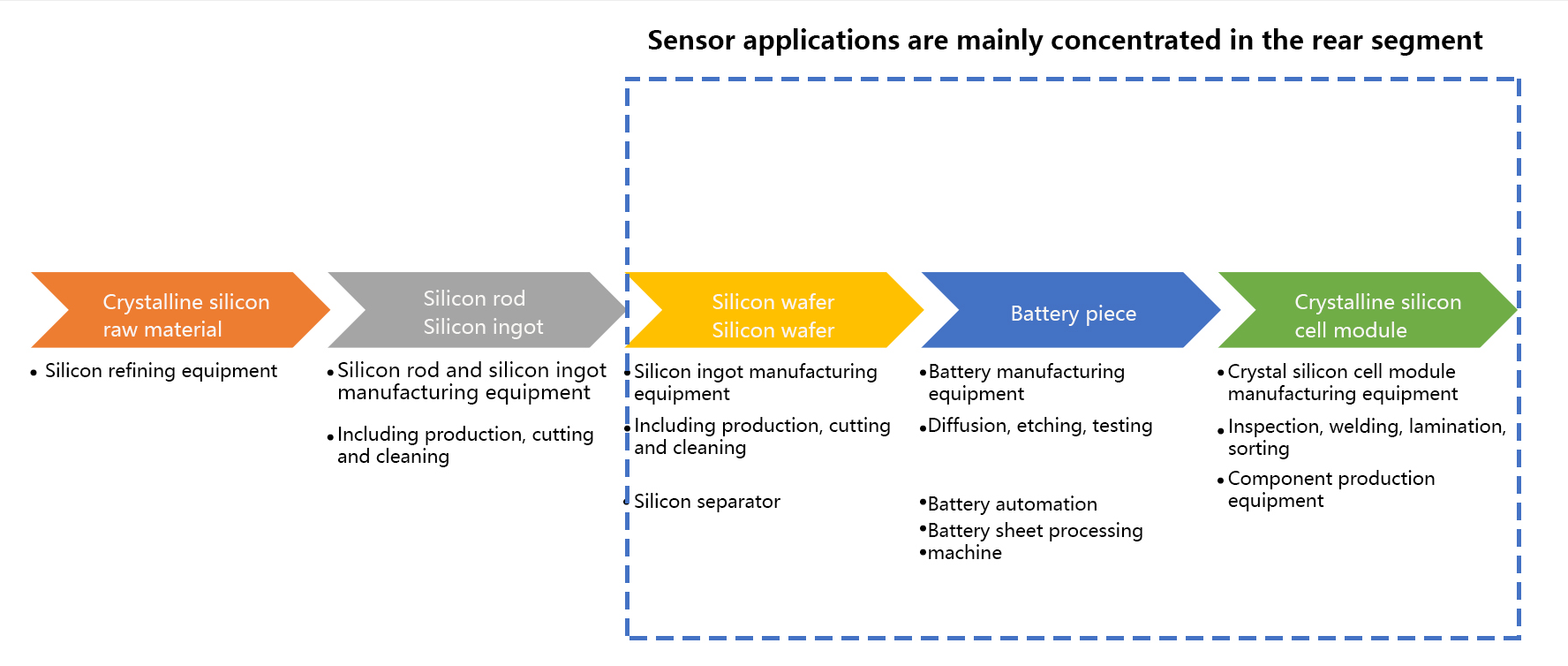

Njengamandla ahlanzekile avuselelekayo, i-photovoltaic idlala indima ebalulekile esakhiweni samandla esizayo. Ngokombono wochungechunge lwezimboni, ukukhiqizwa kwemishini ye-photovoltaic kungafingqwa njengokukhiqizwa kwe-silicon wafer ekhuphukayo, ukukhiqizwa kwe-wafer yebhethri ephakathi nendawo kanye nokukhiqizwa kwamamojula angezansi. Imishini ehlukene yokucubungula ihilelekile kusixhumanisi sokukhiqiza ngasinye. Ngokuthuthukiswa okuqhubekayo kobuchwepheshe bokukhiqiza, izidingo zokunemba zezinqubo zokukhiqiza kanye nempahla yokukhiqiza ehlobene nazo zithuthuka njalo. Esigabeni ngasinye sokukhiqiza inqubo, ukusetshenziswa kwemishini ye-automation kwinqubo yokukhiqiza ye-photovoltaic kudlala indima ebalulekile ekuxhumaniseni okwedlule nesikhathi esizayo, ukuthuthukisa ukusebenza kahle nokunciphisa izindleko.

Amabhethri adlala indima ebalulekile kuyo yonke inqubo yokukhiqiza yemboni ye-photovoltaic. Igobolondo lebhethri eliyisikwele ngalinye lakhiwe igobolondo kanye nekhava yepuleti okuyingxenye eyinhloko yokuqinisekisa ukuphepha kwebhethri ye-lithium. Izovalwa ngegobolondo leseli yebhethri, ukuphuma kwamandla angaphakathi, futhi kuqinisekiswe izingxenye ezibalulekile zokuphepha kweseli yebhethri, enezidingo eziqinile zokuvala ingxenye, ukucindezela kwevalvu yokukhulula, ukusebenza kukagesi, usayizi nokubukeka.

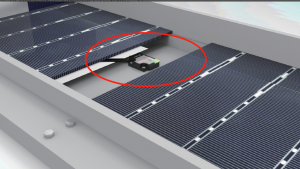

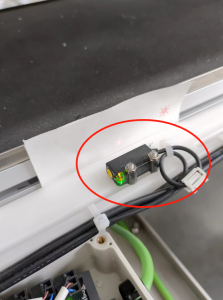

Njengesistimu yezinzwa yemishini ye-automation,inzwainezici zokuzwa okunembile, ukufakwa okuguquguqukayo nokuphendula okusheshayo. Indlela yokukhetha inzwa efanelekile ngokusho kwesimo esithile sokusebenza, ukuze kuzuzwe inhloso yokunciphisa izindleko, ukwanda kokusebenza kahle nokusebenza okuzinzile. Kunezimo ezihlukahlukene zokusebenza enqubweni yokukhiqiza, ukukhanya okuhlukile okuzungezile, isigqi esihlukile sokukhiqiza kanye namawafa e-silicon emibala ehlukene, njenge-silicon ngemva kokusika idayimane, i-silicon empunga kanye ne-wafer eluhlaza okwesibhakabhaka ngemva kokumbozwa kwe-velvet, njll. kokubili kunezidingo eziqinile. Inzwa ye-Lanbao inganikeza isixazululo esivuthiwe sokuhlanganisa okuzenzakalelayo nokukhiqizwa kokuhlolwa kwepuleti lekhava yebhethri.

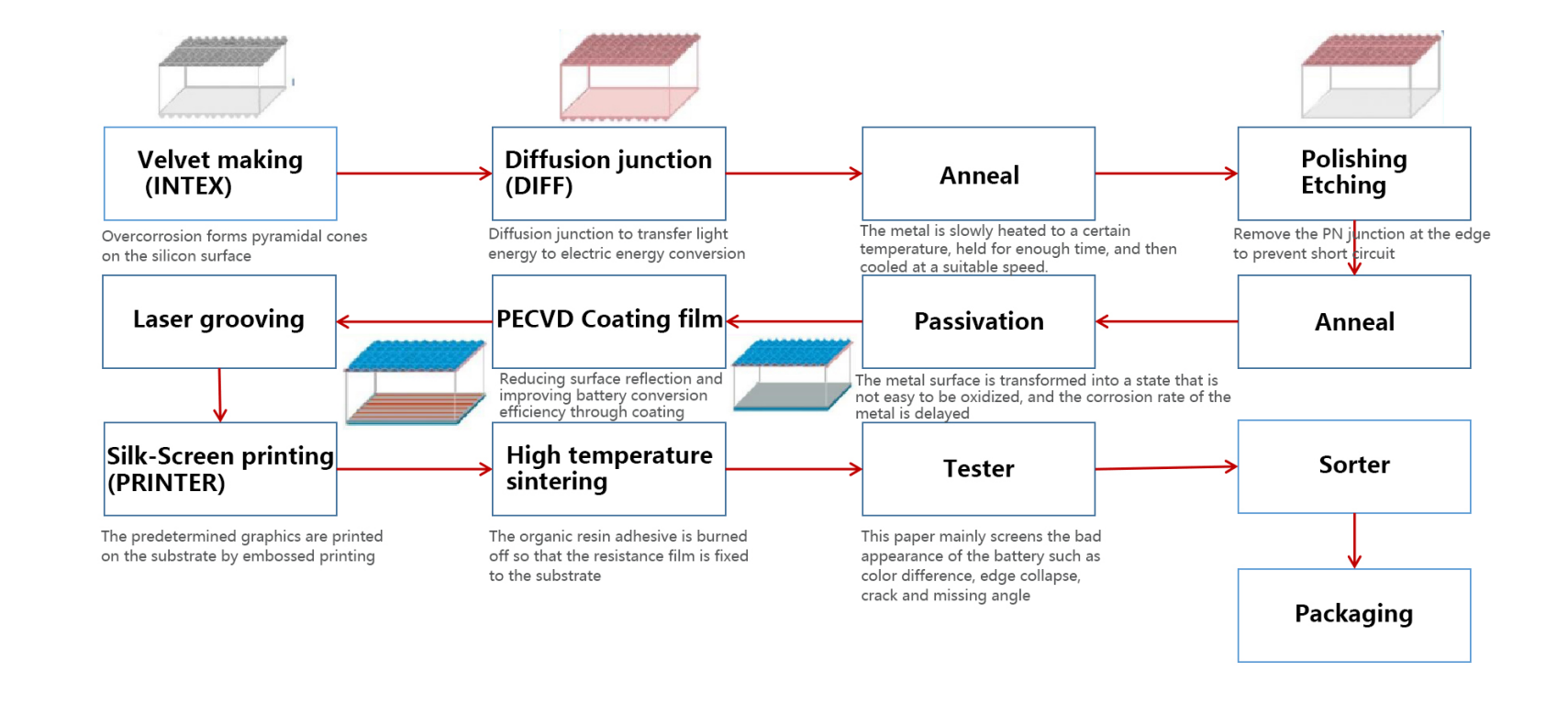

I-Passivated Emitter Rear Contact, okungukuthi i-passivation emitter kanye nobuchwepheshe bebhethri le-back passivation. Ngokuvamile, ngesisekelo samabhethri avamile, i-aluminium oxide nefilimu ye-silicon nitride ifakwe ngemuva, bese ifilimu ivulwa nge-laser. Njengamanje, ukusebenza kahle kokuguqulwa kwamaseli enqubo ye-PERC sekusondele kumkhawulo wethiyori wama-24%.

Izinzwa ze-Lanbao zicebile ngezinhlobo futhi zisetshenziswa kabanzi ezigabeni ezihlukahlukene zenqubo yokukhiqizwa kwebhethri ye-PERC. Izinzwa ze-Lanbao azikwazi nje ukufeza ukuma okuzinzile nokunembile kanye nokutholwa kwendawo, kodwa futhi zihlangabezane nezidingo zokukhiqiza ngesivinini esikhulu , ukukhulisa ukusebenza kahle nokunciphisa izindleko zokukhiqiza i-photovoltaic.

Izinhlelo zenzwa zomshini weselula

| Isikhundla sokusebenza | Isicelo | Umkhiqizo |

| I-oven yokuhlanza, ILD | Ukutholwa kwendawo yemoto yensimbi | Inzwa ye-Inductive-Uchungechunge olumelana nezinga lokushisa eliphezulu |

| Imishini yokukhiqiza ibhethri | Ukutholwa kwendawo ye-silicon wafer, i-wafer carrier, isikebhe sikaloliwe kanye nesikebhe segraphite | I-Photoelectric Sensoe-I-PSE-Polarized reflection series |

| (Ukuphrinta kwesikrini, umugqa wethrekhi, njll.) | ||

| Isiteshi somhlaba wonke - Imojula yokunyakaza | Indawo yoqobo | Inzwa kagesi wesithombe-PU05M/PU05S slot uchungechunge slot |

Izinhlelo zenzwa zomshini weselula

| Isikhundla sokusebenza | Isicelo | Umkhiqizo |

| Imishini yokuhlanza | Ukutholwa kwezinga lepayipi | Inzwa Enamandla-CR18 uchungechunge |

| Umugqa wethrekhi | Ukutholwa kobukhona kanye nokutholwa kwendawo ye-silicon wafer; Ukutholwa kobukhona besithwali se-wafer | Inzwa enamandla-CE05 uchungechunge,CE34 uchungechunge, Inzwa kagesi-Uchungechunge lwe-PSV(i-convergent relection), uchungechunge lwe-PSV (ukucindezelwa kwe-backgroud) |

| Ukudluliswa kwethrekhi | Ukutholwa kwesithwali se-wafer kanye nendawo yesikebhe se-quartz | Inzwa ye-Cpacitive-CR18 uchungechunge, inzwa ye-photoelectric-Uchungechunge lwe-PST(ukucindezelwa kwangemuva/ ngokuboniswa kwe-beam), uchungechunge lwe-PSE (ngokuboniswa kwe-beam) |

| Inkomishi yokumunca, i-buff ngezansi, i-mechanical lift | Ukuthola ubukhona be-silicon chips | Inzwa kagesi wesithombe-Uchungechunge lwe-PSV(convergent reflection), uchungechunge lwe-PSV (ukucindezelwa kwe-backgroud), Inzwa ye-Cpacitive-CR18 uchungechunge |

| Imishini yokukhiqiza ibhethri | Ukutholwa kobukhona be-wafer carrier kanye ne-silicon chips/ Ukutholwa kwesikhundla se-quartz | Inzwa kagesi wesithombe-Uchungechunge lwe-PSE(ukucindezelwa kwangemuva) |

Isikhathi sokuthumela: Jul-19-2023