Sensors have become increasingly indispensable in modern engineering machinery. Among them, proximity sensors, renowned for their non-contact detection, rapid response, and high reliability, have found widespread applications in various engineering machinery equipment.

Engineering machinery typically refers to heavy-duty equipment that performs primary tasks in various heavy industries, such as construction machinery for railways, roads, water conservancy, urban development, and defense; energy machinery for mining, oil fields, wind power, and power generation; and common engineering machinery in industrial engineering, including various types of excavators, bulldozers, crushers, cranes, rollers, concrete mixers, rock drills, and tunnel boring machines. Given that engineering machinery often operates in harsh conditions, such as heavy loads, dust intrusion, and sudden impact, the structural performance requirements for sensors are exceptionally high.

Where proximity sensors are commonly used in engineering machinery

-

Position Detection: Proximity sensors can accurately detect the positions of components such as hydraulic cylinder pistons and robotic arm joints, enabling precise control of engineering machinery movements.

-

Limit Protection: By setting proximity sensors, the operating range of engineering machinery can be limited, preventing the equipment from exceeding the safe working area and thus avoiding accidents.

-

Fault Diagnosis: Proximity sensors can detect faults such as wear and jamming of mechanical components, and promptly issue alarm signals to facilitate maintenance by technicians.

-

Safety Protection:Proximity sensors can detect personnel or obstacles and promptly stop equipment operation to ensure the safety of operators.

Typical uses of proximity sensors on mobile engineering equipment

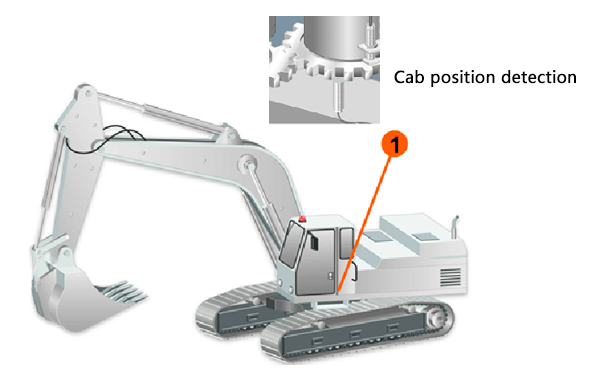

Excavator

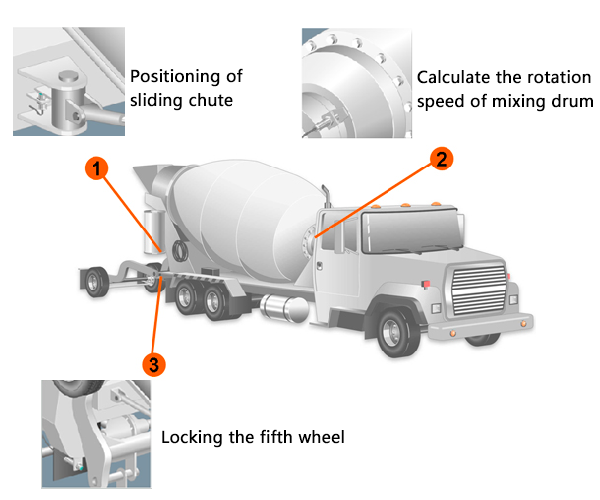

Concrete mixer truck

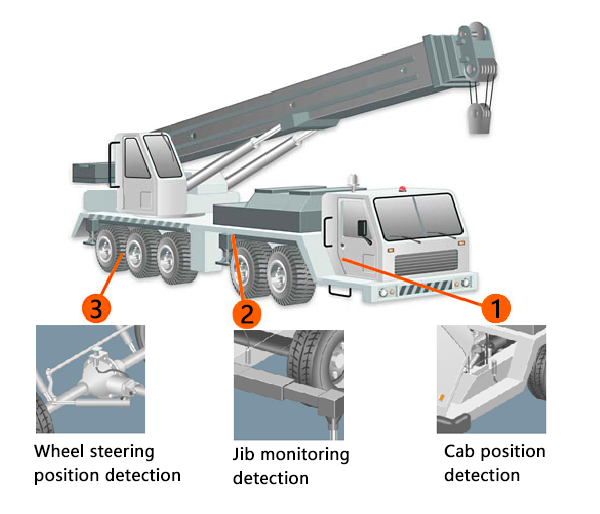

Crane

Lanbao's Recommended Choice: High Protection Inductive Sensors

-

IP68 Protection, Rugged and Durable: Withstands harsh environments, rain or shine.

Wide Temperature Range, Stable and Reliable: Operates flawlessly from -40°C to 85°C.

Long Detection Distance, High Sensitivity: Meets diverse detection needs.

PU Cable, Corrosion and Abrasion Resistant: Longer service life.

Resin Encapsulation, Safe and Reliable: Enhances product stability.

| Model | LR12E | LR18E | LR30E | LE40E | ||||

| Dimensions | M12 | M18 | M30 | 40*40*54mm | ||||

| Mounting | Flush | Non-flush | Flush | Non-flush | Flush | Non-flush | Flush | Non-flush |

| Sensing distance | 4mm | 8mm | 8mm | 12mm | 15mm | 22mm | 20mm | 40mm |

| Guaranteed distance(Sa) | 0…3.06mm | 0…6.1mm | 0…6.1mm | 0…9.2mm | 0…11.5mm | 0…16.8mm | 0…15.3mm | 0…30.6mm |

| Supply viltage | 10…30 VDC | |||||||

| Output | NPN/PNP NO/NC | |||||||

| Consumption current | ≤15mA | |||||||

| Load current | ≤200mA | |||||||

| Frequency | 800Hz | 500Hz | 400Hz | 200Hz | 300Hz | 150Hz | 300 Hz | 200Hz |

| Protection degree | IP68 | |||||||

| Housing material | Nickel-copper Alloy | PA12 | ||||||

| Ambient temperature | -40℃-85℃ | |||||||

Post time: Aug-15-2024