In the rapidly advancing landscape of industrial production, the flatness of product surfaces is a crucial indicator of product quality. Flatness detection is widely used across various industries, such as automotive manufacturing, aerospace, and electronics. Examples include flatness inspection of batteries or mobile phone housings in the motor industry, and flatness inspection of LCD panels in the semiconductor industry.

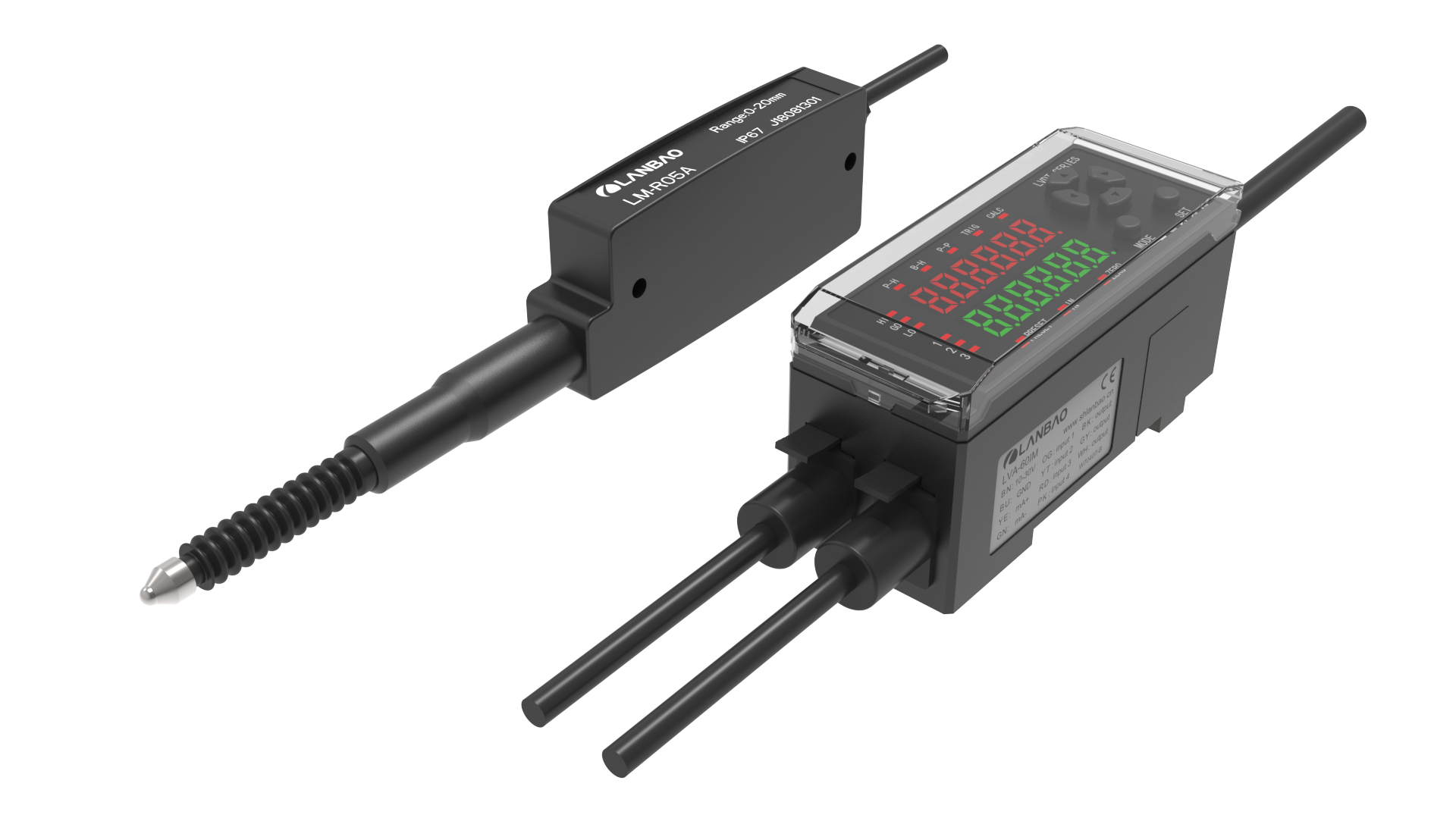

However, traditional flatness detection methods suffer from issues such as low efficiency and poor accuracy. In contrast, LVDT (Linear Variable Differential Transformer) sensors, with their advantages of high precision, high reliability, and frictionless measurement (for example: LVDTs use a probe to contact the object surface, driving the core displacement to achieve frictionless and high-precision measurement), are now widely used in modern object flatness detection.

Operating Principle:

Frictionless Measurement: There is normally no physical contact between the movable core and the coil structure, meaning the LVDT is a frictionless device.This permits its use in critical measurements that can't tolerate friction loading.

Unlimited Mechanical Life: Because there is normally no contact between the LVDT's core and coil structure, no parts can rub together or wear out, giving LVDTs an essentially unlimited mechanical life.This is especially important in high-reliability applications.

Infinite Resolution: LVDTs can measure infinitesimally small changes in core position because they operate on electromagnetic coupling principles in a friction-free structure.The only limitation on resolution is the noise in the signal conditioner and the resolution of the output display.

Null Point Repeatability: The location of an LVDT's intrinsic null point is extremely stable and repeatable, even over its very wide operating temperature range.This makes LVDTs perform well as null position sensors in closed-loop control systems.

Cross-Axis Rejection: LVDTs are very sensitive to axial movement of the core and relatively insensitive to radial movement.This allows LVDTs to be used to measure cores that are not moving in a precise straight line.

Fast Dynamic Response: The absence of friction during ordinary operation permits an LVDT to respond very fast to changes in core position.The dynamic response of an LVDT sensor itself is limited only by the inertial effects of the core's slight mass.

Absolute Output: The LVDT output is an analog signal directly related to position. If a power outage occurs, measurement can be resumed without recalibration (the power needs to be turned back on to obtain the current displacement value after a power outage).

- Workpiece Surface Flatness Detection: By contacting the surface of a workpiece with an LVDT probe, height variations on the surface can be measured, thereby assessing its flatness.

- Sheet Metal Flatness Detection: During sheet metal production, an arrayed LVDT layout, combined with an automated scanning mechanism, can achieve full-surface flatness mapping of large-sized sheets.

- Wafer Flatness Detection: In the semiconductor industry, the flatness of wafers has a significant impact on chip performance. LVDTs can be used to precisely measure the flatness of wafer surfaces. (Note: In wafer flatness detection, the LVDT needs to be equipped with lightweight probes and a low contact force design, making it suitable for scenarios where damage to the surface is not allowed.)

- Micrometer-level repeatability

- Multiple ranges available from 5-20mm

- Comprehensive output options,including digital signal,analog,and 485.

- Low as 3N sensing head pressure,capable of non-abrasive detection on both metal glass surfaces.

- Rich exterior dimensions to meet various application spaces.

- Selection guide

| Type | Part name | Model | Rang | Linearity | Repeatability | Output | Protection grade |

| Combinedprobe type | Amplifier | LVA-ESJBI4D1M | / | / | / | 4-20mA current,three ways digital output | IP40 |

| Sensing probe | LVR-VM15R01 | 0-15mm | ±0.2%F.S. (25℃) |

8μm(25℃) | / | IP65 | |

| LVR-VM10R01 | 0-10mm | ||||||

| LVR-VM5R01 | 0-5mm | ||||||

| Integrated type | Integrated sensing prbe | LVR-VM20R01 | 0-20mm | ±0.25%F.S. (25℃) |

8μm(25℃) | RS485 | |

| LVR-VM15R01 | 0-15mm | ||||||

| LVR-VM10R01 | 0-10mm | ||||||

| LVR-VM5R01 | 0-5mm | ||||||

| LVR-SVM10DR01 | 0-10mm |

Post time: Feb-11-2025