With the development of modern technology, the application of robots in manufacturing is becoming more and more widespread. However, while robots improve production efficiency and quality, they also face new safety challenges. Ensuring the safety of robots during the work process is not only related to the life safety of operators, but also directly affects the production efficiency and economic benefits of enterprises.

To ensure that robots do not cause harm to operators or the surrounding environment during the work process, measures such as mechanical protection, electrical protection, software protection, and environmental protection are often taken.

Safety door switches are a type of safety device that belongs to electrical protection measures. They are used to monitor and control the opening and closing status of doors, thereby ensuring workplace safety. They are also known as safety door locks, safety switches, safety interlock switches, electromagnetic locking safety switches, etc.

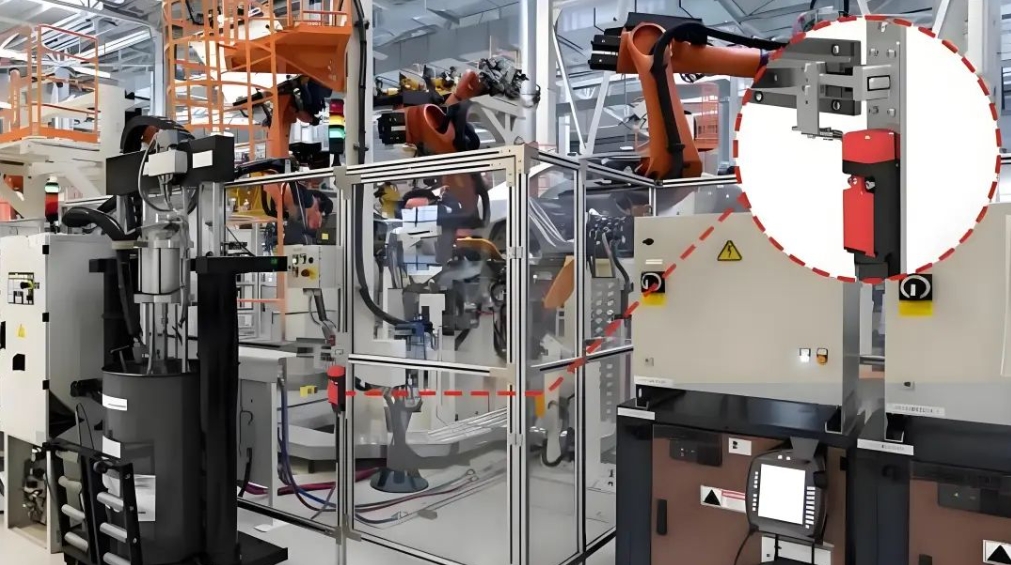

Industrial Robot Workstation

Restrict access to hazardous areas

To prevent personnel from accidentally entering and causing personal injury, safety fences are set up around the robot's work cell or station, and safety door interlocks are installed at the entrances of the fences. When the safety door is opened, the robot will automatically stop running.

Safety during maintenance and commissioning

When the robot needs to be maintained or debugged, after the maintenance personnel opens the safety door lock, the equipment in the protected area will automatically power off and stop running to ensure the safety of the maintenance personnel.

Automated production line

Safety protection for collaborative work equipment

In automated production lines, robots work collaboratively with other equipment, and safety door interlocks are used to monitor the safety status of equipment maintenance access and material loading/unloading channels.

Automotive Body-in-White (BIW) Welding Shop

In the welding workshop of automobile manufacturing, welding robots usually operate in high-temperature and high-speed environments. By monitoring the status of safety door interlocks, it is ensured that the doors are securely closed when the robots are running, and maintenance personnel can only request safe entry after the robots have stopped running.

Safety system integration

Use in conjunction with other safety devices

Safety door interlocks can be used in conjunction with other safety devices such as safety light curtains and emergency stop buttons to form a complete safety protection system.

With the continuous advancement of technology, the application of sensors in the field of robotics will become more and more extensive and in-depth. LANBAO Sensing will continue to enhance the research and exploration of high-end, intelligent, and precision sensors, providing more powerful support for the intelligent development of robots.

Post time: Feb-19-2025