In today's era, data has become a core element driving production efficiency, enhancing quality control, and optimizing supply chain management. Barcode readers, as an indispensable key device in industrial automation, are not only front-end tools for data collection but also bridges connecting the physical world with the digital world.

The primary function of code readers is to quickly and accurately identify and decode various encoded information, such as one-dimensional barcodes, two-dimensional QR codes, and direct part markings. These encodings are widely used in industries like manufacturing, logistics and warehousing, food and beverage, automotive manufacturing, and electronics and semiconductors, carrying data from the entire lifecycle of products, from raw material procurement and production processing to product delivery.

Through code, this data can be efficiently collected and transmitted in real-time to industrial control systems, thereby enabling precise monitoring of production processes, quality traceability, and optimized supply chain management.

In the logistics sector,code readers can quickly identify barcodes on packages, enabling automated sorting and inventory management; in automotive manufacturing, they are used to track the source and production status of components, ensuring quality traceability; in the electronics manufacturing industry, code readers focus on identifying tiny DPM codes, ensuring precision and accuracy in the production process.

Code reader usability

Seamless data integration

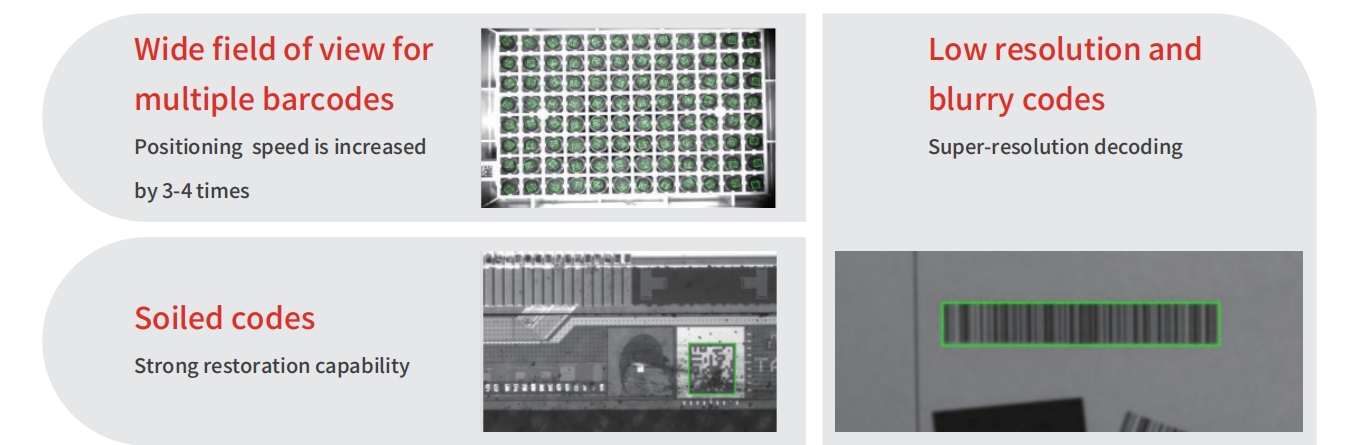

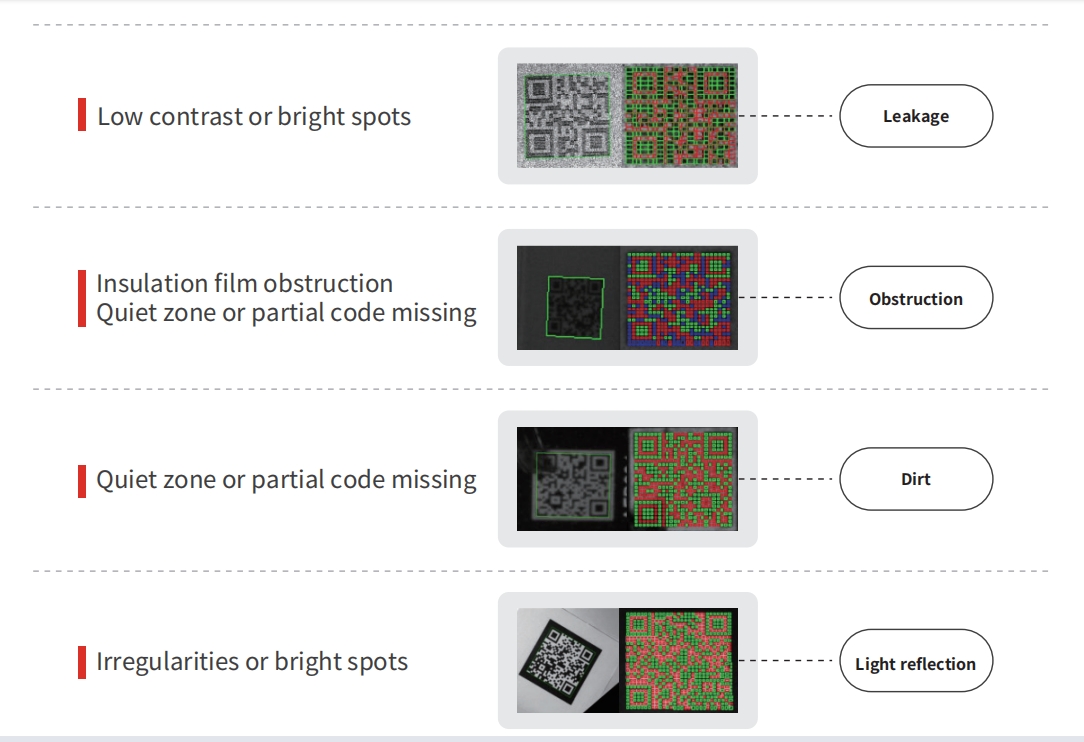

Utilizing deep learning algorithms for faster and stronger reading

Industry optimization

Diverse Product Portfolio, Wide Applicability:

Wide pixel distribution from 100 to 800W, catering to various scenarios.

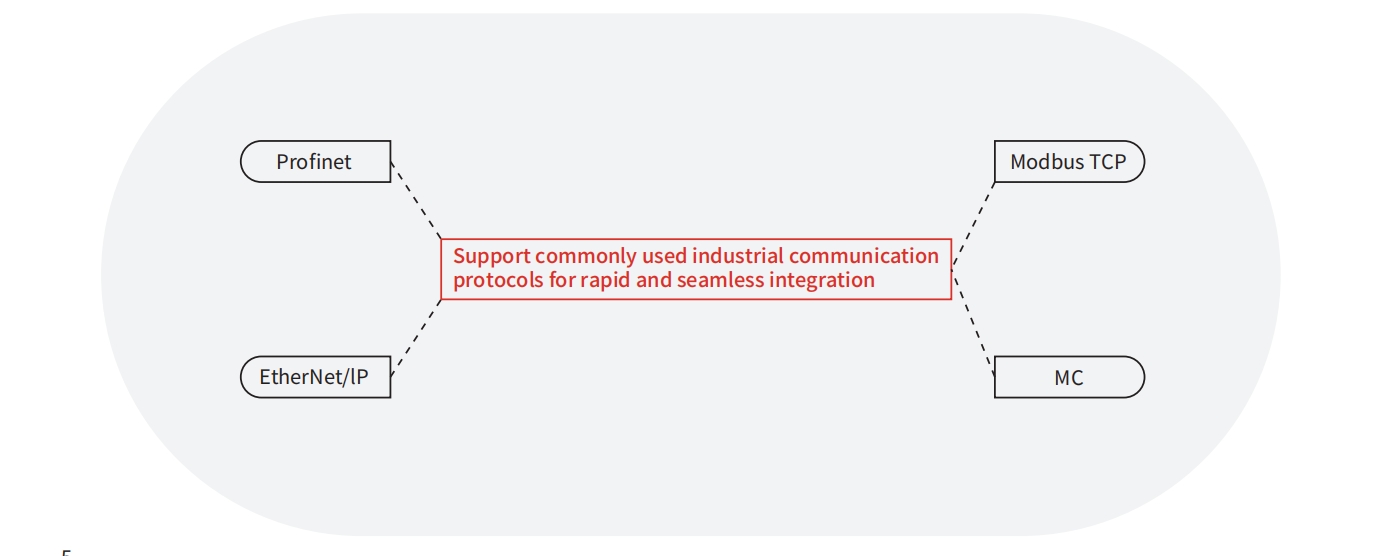

Rich Interfaces, Worry-Free Communication:

Abundant interfaces, ensuring seamless communication with physical communication interfaces such as Ethernet ports, serial ports, and USB, facilitating smooth communication with devices like PCs and PLCs.

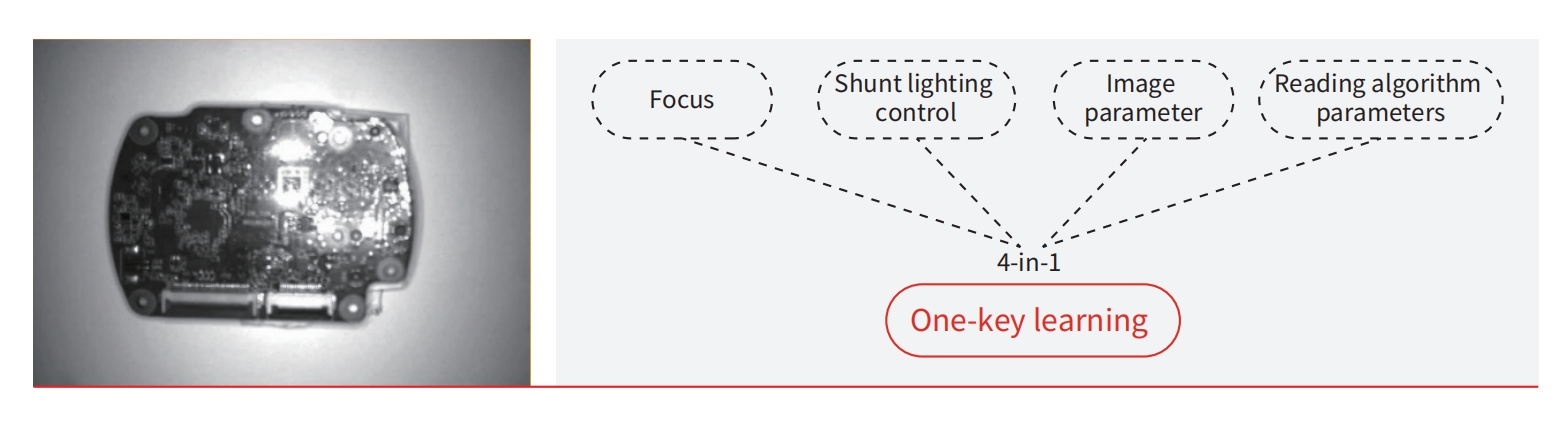

One-Key Adjustment, Intelligent Recognition:

One-button operation for automatic adjustment of focus and acquisition parameters, enabling autonomous recognition of multiple code types.

Support for Customized Barcode Grading and Data Analysis:

Supports customized barcode grading, data analysis, and other functions.

With the continuous advancement of technology, the functions of barcode readers are also constantly expanding, from simple data collection to intelligent data analysis, from standalone devices to deep integration with automated production lines. Barcode readers are gradually becoming core components of industrial automation.

In the future, with the introduction of artificial intelligence, machine learning, and multispectral imaging technologies, barcode readers will possess stronger adaptability and higher efficiency, injecting new vitality into the development of industrial automation.

Post time: Mar-06-2025