The new energy wave is sweeping in, and the lithium battery industry has become the current “trendsetter”, and the manufacturing equipment market for lithium batteries is also rising. According to EVTank’s prediction, the global lithium battery equipment market will exceed 200 billion yuan in 2026. With such a broad market prospect, how can lithium battery manufacturers upgrade their equipment, improve their automation level, and achieve a double leap in production capacity and quality in the fierce competition? Next, let’s explore the automatic process of lithium battery into the shell and what Lanbao sensors can help.

Application of Lambo sensor in shell – entering equipment

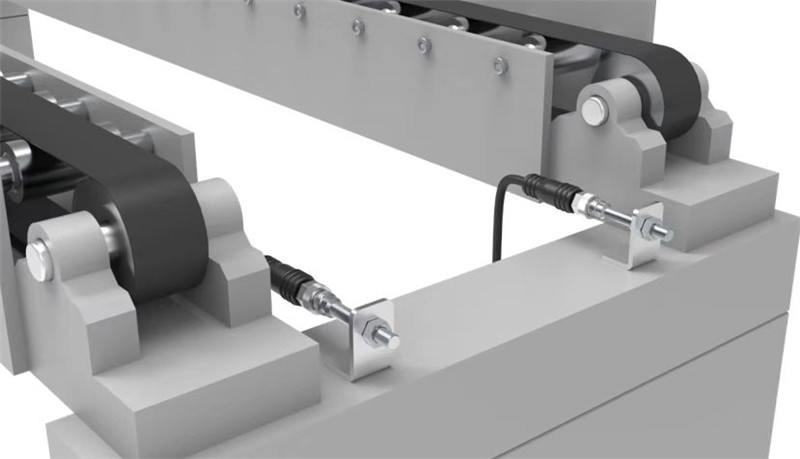

● In place detection of loading and unloading trolley

Lanbao LR05 inductive miniature series can be used for the feeding process of the material tray. When the trolley reaches the specified position for feeding, the sensor will send a signal to drive the belt conveyor tray to enter the station, and the trolley will complete the feeding action according to the signal. This series of products have a variety of sizes and specifications; 1 and 2 times of detection distance are optional, which is convenient for installation in a narrow space and meets the installation requirements of different spaces in the production environment; Excellent EMC technology design, strong anti-interference ability, making the trolley feeding more efficient and stable.

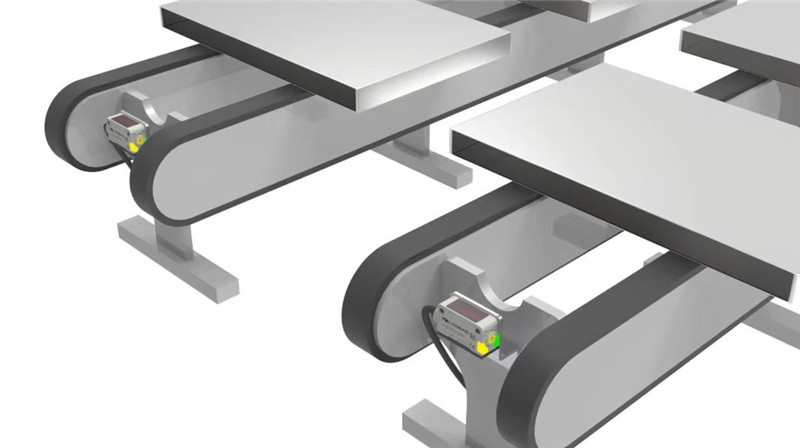

● Battery case in place detection

Lanbao PSE background suppression sensor can be used in the material transportation process. When the battery case reaches the specified position on the material transportation line, the sensor triggers the in place signal to drive the manipulator to the next step. The sensor has excellent background suppression performance and color sensitivity, regardless of color change and with strong anti-interference ability. It can easily detect the shiny battery case in the lighting environment with high brightness; The response speed is up to 0.5ms, accurately capturing the position of each battery case.

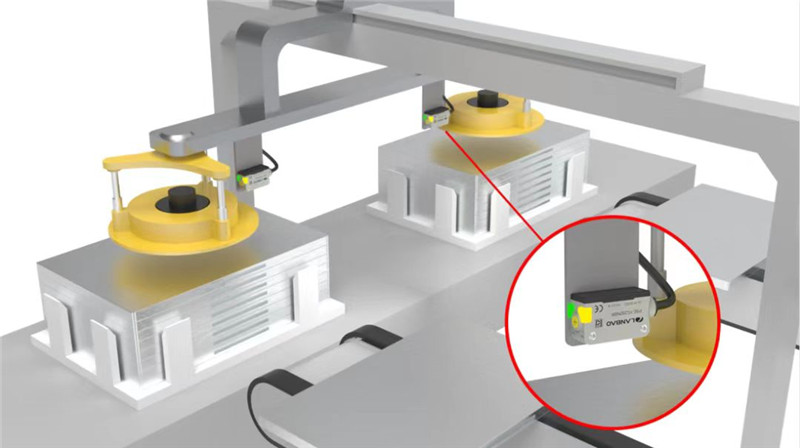

● Whether there is material detection at the gripper

Lanbao PSE convergent sensor can be used in the grasping and positioning process of the manipulator. Before the gripper of the manipulator carries the battery case, the sensor needs to be used to detect the presence of the battery case, so as to trigger the next action. The sensor can stably detect small objects and bright objects; With stable EMC characteristics and anti-interference characteristics; Can be used for accurate detecting existence of materials.

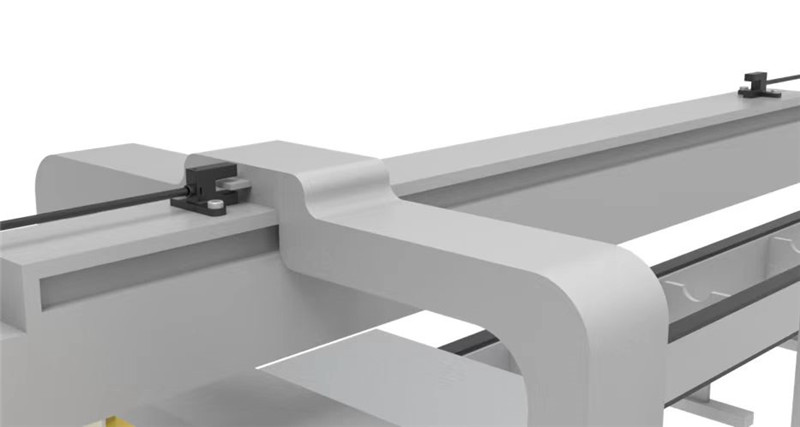

● Tray transfer module positioning

The miniature slot type PU05M series photoelectric sensor can be used in the process of unloading the empty tray.Before the empty material tray is transported out, it is necessary to use a sensor to detect the position of the unloading movement, so as to trigger the next movement.The sensor adopts a flexible bending resistant wire, which is convenient for installation and disassembly, effectively solves the conflict of working and installation space, and accurately ensures that the material tray is empty.

At present, lanbao sensor has provided many lithium battery equipment manufacturers with high-quality products and services to help upgrade the automation industry. In the future, lanbao sensor will adhere to the development concept of taking scientific and technological innovation as the first driving force to meet the digital and intelligent needs of customers in Intelligent Manufacturing Upgrading.

Post time: Aug-17-2022