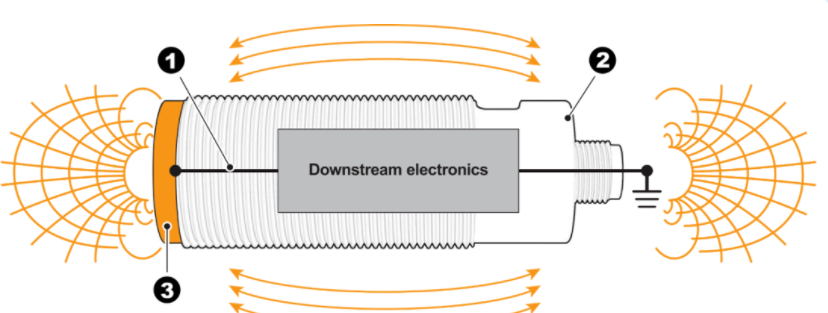

Capacitive proximity switches can be used for contact or non-contact detection of almost any material. With LANBAO's capacitive proximity sensor, users can adjust sensitivity and even penetrate non-metal canisters or containers to detect internal liquids or solids.

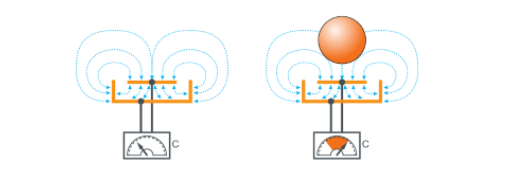

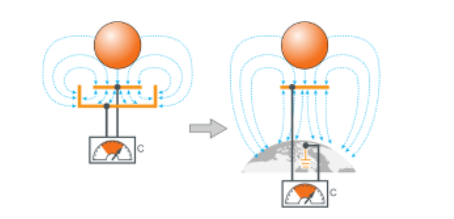

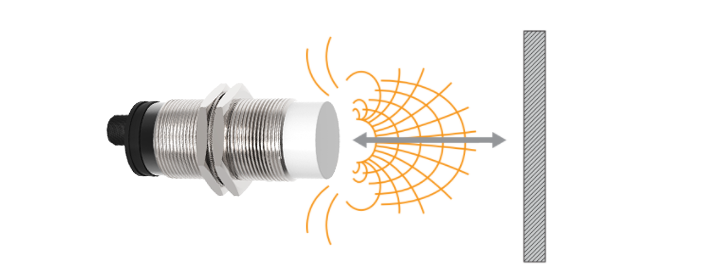

In the case of capacitive sensors, the base sensing element is a single board capacitor and the other plate connection is grounded. When the target moves to the sensor detection area, the capacitance value changes and the sensor output switches.

02 The factors that affect the sensing distance of the sensor

The induced distance refers to the physical distance that causes the switch output to change when the target approaches the sensor's induced surface in the axial direction.

Our product's parameter sheet lists three different distances:

Sensing Range refers to the nominal distance defined in the development process, which is based on a target of a standard size and material.

The Real Sensing Range takes into account component deviation at room temperature. The worst case is 90% of the nominal sensing range.

The Actual Operating Distance takes into account switch point drift caused by humidity, temperature rise and other factors, and the worst case is 90% of the actual induced distance. If the inductive distance is critical, this is the distance to use.

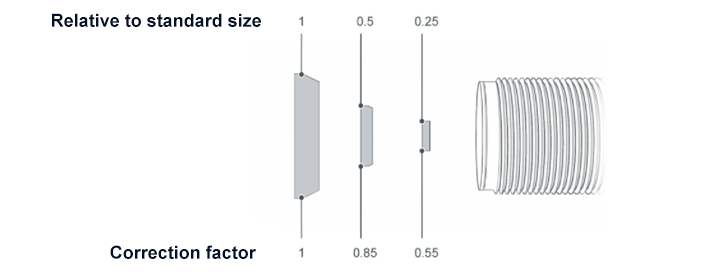

In practice, the object is rarely of standard size and shape. The influence of target size is shown below:

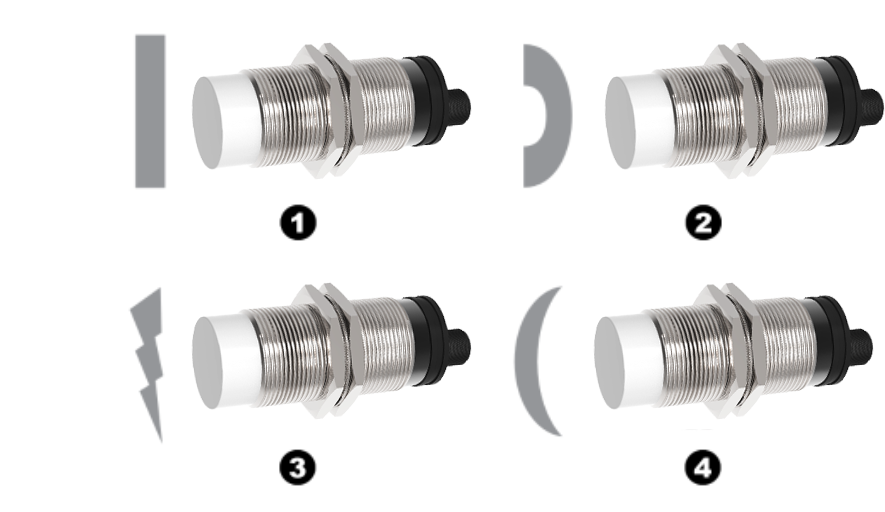

Even less common than the difference in size is the difference in shape. The figure below shows the effect of the shape of the target.

It is actually difficult to provide a shape-based correction factor, so testing is needed in applications where inductive distance is critical.

Finally, the main factor affecting the induced distance is the dielectric constant of the target. For capacitive level sensors, the higher the dielectric constant, the easier the material is to detect. As a general rule of thumb, if the dielectric constant is greater than 2, the material should be detectable. The following are the dielectric constants of some common materials for reference only.

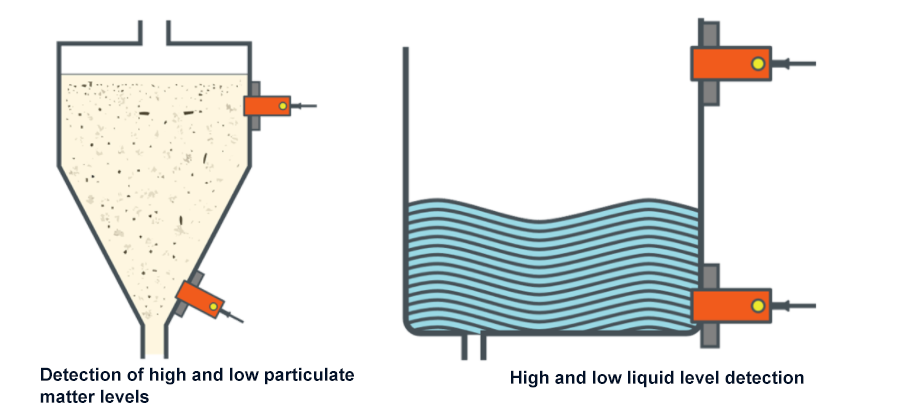

03 Capacitive sensor for level detection

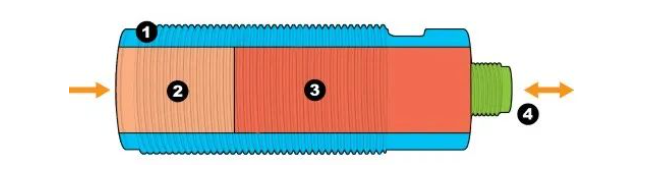

In order to successfully use capacitive sensors for level detection, ensure that:

The walls of the vessel are non-metallic

Container wall thickness less than ¼" -½"

There is no metal near the sensor

The induction surface is placed directly on the wall of the container

Equipotential grounding of sensor and container

Post time: Feb-14-2023